- Main Site

- FIT roof panel vs LAMBDA 2.0 panel - which is the choice for you?

- FIT roof panel vs LAMBDA 2.0 panel – which is the choice for you?

FIT roof panel vs LAMBDA 2.0 panel – which is the choice for you?

21 October 2024

Choosing the right roofing material is crucial to the durability, aesthetics and functionality of the roof. In the BP2 range, the PANEL SERIES product line includes, among others, LAMBDA 2.0 and FIT roof panels. What distinguishes them from each other and which solution will be better for your investment?

Both panels are distinguished by their high quality workmanship, use of innovative technologies and availability in HERCULIT [HC] and ULTIMAT [UTK] coatings. Both also represent a nod to traditional roofing.

Although they are products with similar characteristics, they differ in size (cut-to-size vs modular), installation method and warranty period. In this article, we compare the key features of FIT and LAMBDA 2.0 roof panels to help you make the best choice.

Modernity and aesthetics

One significant difference between LAMBDA 2.0 and FIT panels is the available dimensions and profiling options, which affect the quality of the installation and the final visual effect.

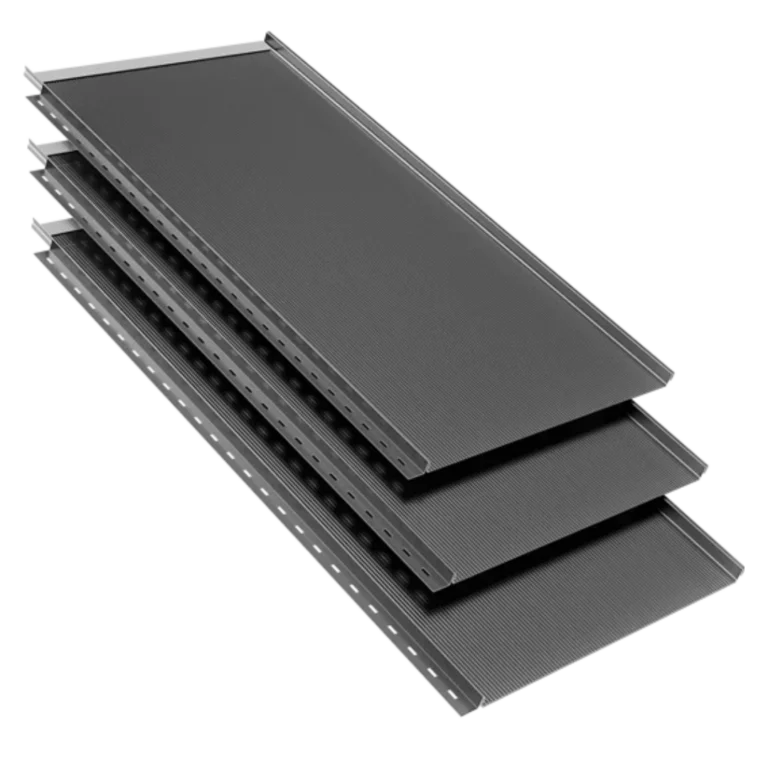

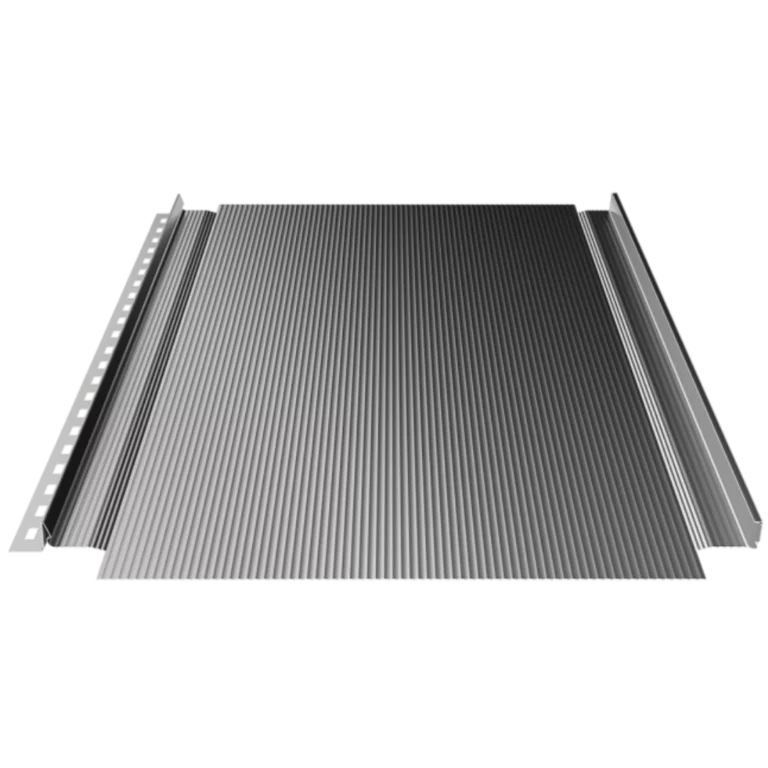

LAMBDA 2.0 is a cut-to-size panel available in two widths (515 mm and 307 mm) and 4 surface types (MICRO RIB, type R, type T25 and smooth).

Covering a standard roof with LAMBDA 2.0 is done with sheets the entire length of the slope (from ridge to eaves – maximum length:10m). This means that the long panel has to be transported from the warehouse to the project site and then to the roof, which sometimes creates difficulties. It is also more susceptible to mechanical damage, such as waving and bending, although it provides more effective coverage.

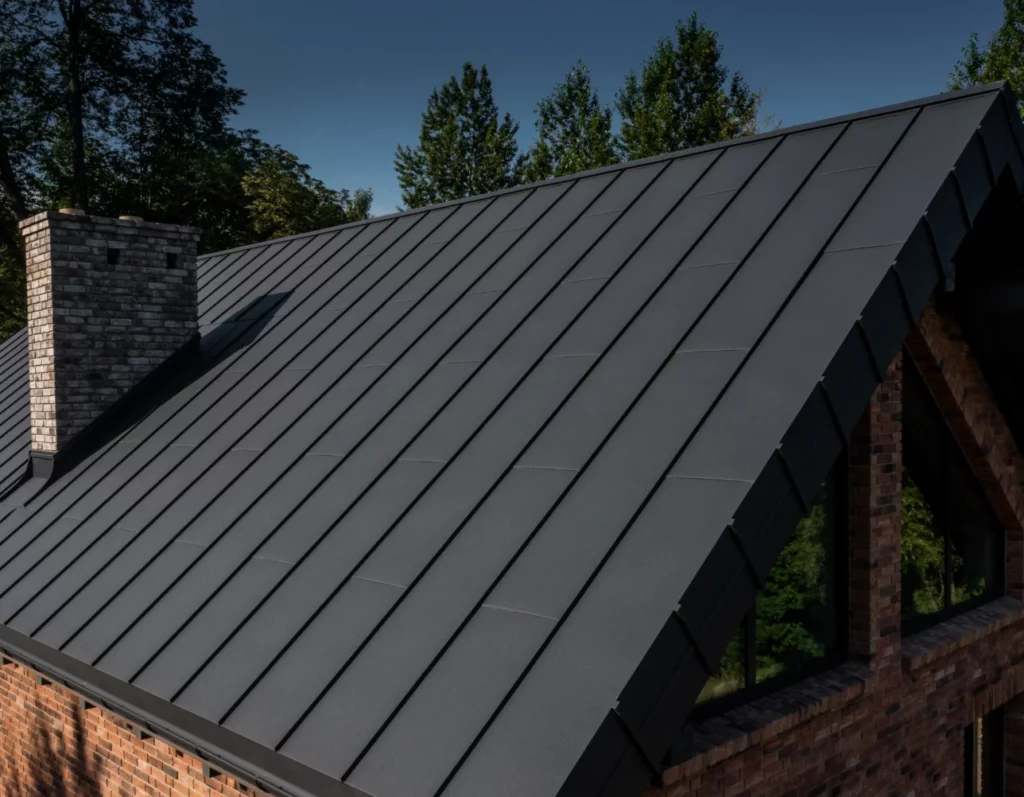

The FIT modular roof panel is available in two lengths, 2050 mm and 1020 mm, making it easier to transport, store and install on the roof. The sheets are lighter and easier to even carry by themselves. The FIT panel is available in two surface versions: smooth and with MICRO RIB longitudinal microprofiling. The shorter sheets combined with MICRO RIB technology significantly minimise the unsightly ripple effect of the panel surface, making the roof look flawless. In addition, the FIT panels are installed in a ‘passing pattern’, which creates a ‘chequerboard’ effect that gives the roof slope a more traditional, but at the same time more interesting character.

Differences in assembly

Both products are installed with a click seam, which is well known and liked by roofers. However, there are some differences that can make a decisive difference to the efficiency of the work carried out.

FIT Modular Panel: The FIT Modular Panel is ready for covering immediately after unpacking – there is no need to specially cut or bend it. Thus, not only are assembly errors minimised, but the final visual effect is also enhanced.

The shorter sheets, combined with MICRO RIB technology, significantly minimise the unsightly ripple effect of the panel surface, making the roof look flawless. Thanks to the panel’s modularity and the proprietary EASY LINK system, installation becomes even simpler – specially cut corners eliminate the problem of overlapping three layers of sheets, and the profile shape ensures a perfect fit of the sheets with no visible longitudinal joints. This enables contractors to realise a roof with the aesthetics of a traditional craftsman’s seam much more quickly and efficiently. In addition, it is the only panel in the range to feature SEAL PROTECT technology – a special sealant is pressed into the fold of the sheet at the manufacturing stage, making the FIT panel even more airtight.

LAMBDA 2.0: This panel features BEND LOCK technology, which allows installation without the need for visible screws at the bottom of the panel. The cut edge is precisely folded, which not only enhances the aesthetics, but also protects the roof from adverse weather conditions. Unfortunately, the disadvantage of LAMBDA 2.0 panels may be their length, which, on the one hand, allows for quick coverage (as one panel covers almost the entire length of the roof slope), but on the other hand, requires extra hands to work or tools to transport the panels to the roof. LAMBDA 2.0 roof panels also require additional installation work, i.e. cutting and bending, which may involve the risk of additional errors.

Logistics and order handling

Choosing a FIT modular panel means much more efficient logistics and transport. Short sheets of ~2m and ~1m allow for easier transport and storage, reducing the risk of damage during transport and minimising the ripple effect.

Compared to LAMBDA 2.0, the FIT roof panel can be supplied more efficiently in small pallets, which is extremely important in terms of logistics. As a result, not as much storage space is required and, in addition, material losses are reduced. The lack of ripple effect on short sheets translates into customer satisfaction and a lower risk of potential complaints.

Protective coatings: HERCULIT and ULTIMAT

Depending on the product you choose, you get different guarantee lengths. In this case, a firm favourite is the FIT modular roof panel, which, irrespective of the coating selected, guarantees a minimum of 10 years more durability than the LAMBDA 2.0 panel.

HERCULIT [HC]: This is a satin coating made of polyurethane-cured polyester with a thickness of 35 μm. It is characterised by high resistance to mechanical damage, corrosion (RC4) and UV radiation (RUV4). For the LAMBDA 2.0 panel, the warranty period is 40 years, while for FIT the manufacturer offers an extended warranty period of up to 55 years.

ULTIMAT [UTK]: This matt coating with a granular structure also has a thickness of 35 μm. It is at least 80% recyclable. The ULTIMAT-coated FIT panel is available with a 30-year guarantee, while the LAMBDA 2.0 panel is available with a 20-year guarantee.

Due to the very high quality of production and material, the FIT roof panel comes with a much longer guarantee.

Efficiency and versatility

Both the LAMBDA 2.0 panel and the FIT modular panel follow in the tradition of roofing and can be installed both on the roof and on the façade. At the same time, they combine a classic look (‘passing’ arrangement) with contemporary installation solutions. However, it is the FIT panel that is more readily chosen and composed with modern architectural styles. In the design industry, it is regarded as a product that more effectively meets the needs of innovative construction. The modular construction of the panels, the greater resistance to waviness and the possibility of passing installation means that a FIT roof not only looks nicer, but also lasts longer, as confirmed by warranties of up to 55 years.

Competitive price

Originally, the LAMBDA 2.0 panel was to be offered as an economical alternative to the more expensive product, the FIT modular roof panel. Fortunately, thanks to developments in production technology, both panels now cost comparably. Today, we can offer you a product with higher quality and a longer guarantee, at a more attractive and lower price.

Summary

Both the LAMBDA 2.0 and FIT roof panels are robust solutions that combine modern technology with the aesthetics of traditional roofs. Each has its strengths, but it is the FIT panel that stands out against the LAMBDA 2.0 in several key aspects. As a technologically newer product, FIT is particularly attractive to those who value not only aesthetics, but also practicality and long-term durability. Although the choice between the two depends on individual needs, the FIT panel seems to be the better option, especially if you are looking for a modern product with a universal appeal.

Fill in the form and receive a quote for our roof panels.

FILL IN THE FORMShare this article with your friends

© Copyright 2025 VSS s.r.o